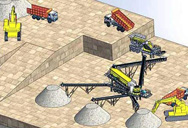

Manganese ore crushing equipment processing technology

The large manganese ore is evenly sent to the jaw crusher or mobile jaw crushing station (primary crushing) by the vibrating feeder through the silo for coarse crushing; After the coarsely crushed manganese ore is screened by vibrating screen, it is sent to the single-cylinder

More

Abrasion wear of austenitic manganese steels via jaw crusher test

2021年7月15日 The abrasion wear of the austenitic manganese steels with 12% Mn and 20% Mn was evaluated via jaw crusher tests. The abrasive mass (i.e. gravel) used per test was

More

Jaw Crusher

The range of MACSALAB Jaw Crushers is ideal for the primary crushing of samples of moderately hard materials, including coal, limestone, ore, minerals, bricks, and rubble. Units

More

Jaw Crushers - Mt Baker Mining and Metals

Mt Baker Mining and Metals offers ready-to-run jaw crushers for various applications, such as mining, construction, and recycling. See sizes, features, prices, and customer reviews of their diesel and electric powered jaw crushers.

More

Top 10 Manganese Beneficiation Machines for Efficient Processing

2024年4月28日 Jaw crushers are commonly used in the initial stage of manganese ore processing. They are designed to crush large chunks of manganese ore into smaller particles

More

Equipment Required To Build A Manganese Ore

2024年10月25日 The process begins with an initial crushing stage, where large pieces of manganese ore are broken into more manageable sizes. This is usually achieved using jaw crushers or impact crushers, which can

More

Industrial Solutions Jaw crushers - ThyssenKrupp

Crushing jaws made of high-grade aus-tenitic manganese steel, cheek plates made of high-strength special steel. Crushing jaws can freely expand, avoid-ing the transmission of high

More

5 Easy but Efficient Steps to Realize Manganese Ore

2023年4月10日 Manganese ore crushing is the first step in the process, which involves conventional multi-stage crushing equipment. Process flow: Vibrating feeder → jaw crusher → hydraulic cone crusher → vibrating screen

More

Jaw Crushers

Jaw Crushers reduce large size rocks or ore by placing the rock into compression. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the

More

Jaw Crushers RSE Projects

Final sizes range from 5mm to 25mm, dependant on the jaw crusher model. Jaw Crusher 10” x 16” accepts product feed size of 200mm, crushing it down to less than 25mm This crusher is capable of crushing large volumes up to 20 ton per hour of iron ore, manganese ore, chrome ore, platinum ore, gold ore, copper, coal. Jaw Crusher 6” x 10 ...

More

Jaw Crushers - Mt Baker Mining and Metals

I bought a 10″ x 16″ jaw crusher from Mt. Baker Mining in February 2014 for crushing concrete and demolition debris. I have installed a 37 hp gasoline motor on the crusher so it is mobile and I can haul it on the back of my truck. The

More

Cone Crusher_Jaw Crusher_Stone Crusher_Xingaonai

Suitable for crushing stones of iron ore, copper ore, gold ore, manganese ore and other minerals. ... How to effectively reduce the maintenance cost of jaw crusher? Jaw crushers are widely used in the crushing of various ores and

More

Jaw Crusher Explained - saVRee

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width. If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimension.

More

5 Easy but Efficient Steps to Realize Manganese Ore Processing

2023年4月10日 Next, I will introduce the detailed manganese ore processing production line to you. 1. Manganese ore crushing process and equipment Manganese ore crushing is the first step in the process, which involves conventional multi-stage crushing equipment. Process flow: Vibrating feeder → jaw crusher → hydraulic cone crusher → vibrating screen

More

Jaw Crusher Diagram: Simplified Guide - JXSC

2024年2月18日 It’s this dynamic crushing angle and action that sets the jaw crusher apart as a primary crusher. The manganese steel jaw plates, one fixed and the other oscillating in a rhythmic pattern, exert compressive forces that shatter rock and mineral with remarkable efficiency at the receiving opening.

More

Five Kinds Technology Of Manganese Ore Beneficiation

2024年10月25日 After primary crushing, manganese ore goes through another stage called secondary crushing. It involves using a finer crusher or grinder to crush the particles into smaller sizes. The grinding and classification method separates manganese ore into particles of different sizes through grinding and classification for further processing.

More

Crushing in Mineral Processing - 911Metallurgist

2015年12月26日 The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS. Throw = OSS – CSS. OSS and CSS will define a crusher’s performance. The throw of the crusher is the distance that moving jaw moves in going from OSS to CSS. The capacity is a function of size and OSS.

More

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER ...

2017年6月30日 Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing.

More

Kinglink PEX250X1000 PEX1039 Jaw Crusher Manganese Ore

More details — New Kinglink PEX250X1000 PEX1039 Jaw Crusher Manganese Ore . English. English . KINGLINK PEX1039 Fine Jaw Crusher in stock Max feeding size 210mm Discharge size 25-60mm Power 30kw Weight 65000kgs; CE ... Crushing equipment parts . Kinglink jaw plates . Company. About us Help Seller's contacts. International / English

More

Product datasheet Jaw crusher liners High-quality jaw and

Austenitic manganese steel is the industry standard material for jaw crusher liners. Due to its ability to work-harden during operation, it has proven to be versatile, and works well in a majority of applications. We offer three standard grades for jaw crusher liners, allowing you to quickly address changing ore characteristics. By

More

Crusher - Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to

More

How Does a Jaw Crusher Work? A Simple Guide - JXSC

2024年2月5日 Jaw Crusher: 500 mm to 800 mm: Reduced to about 125 mm to 150 mm. Large chunks of material are fed into the jaw crusher where strong compressive forces break them down. Secondary Crushing: To refine the

More

INTBUYING 100x60 Manganese Steel Mini Jaw Crusher Small Crusher

2021年6月15日 INTBUYING 100x60 Mini Jaw Crusher . This jaw crusher is made of manganese steel which has more hardness than carbon steel. It is applicable to medium and fine crushed materials for the purposes of laboratory and production and primarily provided as environmental protection equipment for coal, electric power, mine, geology, chemical,

More

Industrial Solutions Jaw crushers - ThyssenKrupp

peaks in the crusher • Crushing jaws made of high-grade aus - tenitic manganese steel, cheek plates made of high-strength special steel • Crushing jaws can freely expand, avoid - ing the transmission of high stresses to other components • Enhanced crushing jaw profile and crushing chamber geometry, optimized for all kinds of feed material

More

Top 10 Manganese Beneficiation Machines for Efficient Processing

2024年4月28日 Manganese beneficiation machines are essential tools for efficient processing of manganese ores. The top 10 machines discussed in this article, including magnetic separators, jig machines, shaking tables, hydrocyclones, spiral classifiers, flotation machines, high-intensity magnetic separators, centrifugal concentrators, magnetic pulsating separators, and

More

Kinglink PEX250X1000 PEX1039 Jaw Crusher Manganese Ore

More details — New Kinglink PEX250X1000 PEX1039 Jaw Crusher Manganese Ore . English. English . KINGLINK PEX1039 Fine Jaw Crusher in stock Max feeding size 210mm Discharge size 25-60mm Power 30kw Weight 65000kgs; CE ... Crushing equipment parts . Kinglink jaw plates . Company. About us Help Seller's contacts. International / English

More

Jaw Crusher - TAYMACHINERY

Eccentric Shaft: Rotates, causing the movable jaw to move back and forth. Toggle Plate: A toggle plate plays a role in adjusting the outlet of the crusher. Working Principle: Feed Material: Rocks or ore are fed into the top of the crusher through a hopper or feeder. Crushing: The movable jaw compresses the material against the fixed jaw ...

More

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER ...

2017年6月30日 Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing.

More

SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

2017年3月4日 Ore, Copper Ore, Zinc Ore and Manganese Ore. ... The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] ...

More