Surface modification of silica powder by mild ball milling

2022年11月5日 Surface modification of silica particles without a catalyst or solvent was performed using mild ball milling. The effects of the amount of the modifier,

More

Zirconium Silicate Beads Zirpro

Saint-Gobain ZirPro stabilized zirconia and zirconium silicate ceramic beads provide a class-leading range of ceramic grinding media, with different densities and sizes to meet the process requirements of point, ink and coating

More

Silica - NETZSCH Grinding Dispersing

Silica is one of the most complex and most abundant families of materials, existing as a compound of several minerals and as synthetic product. Glass: When silica is heated long enough and hot enough, even without any other

More

Surface modification of silica powder by mild ball milling

2022年11月5日 This technique can form the homogeneous monolayer for the large scale on the surface of materials without any solvents and within a shorter time than that of the wet

More

Silica IMA Europe

Dry grinding in rotary mills, using beach pebbles or alumina balls as grinding media is the most common way to produce silica and cristobalite flour. Since the natural resources of cristobalite

More

Ultra-fine grinding of silicate materials under the use of new resin ...

To reduce the conventionally time-consuming, complex polishing process with loose grain, an interesting approach with novel resin bond grinding tools is presented for surface smoothing.

More

Wet Dry Silica Sand Ball Mill for Silica Sand Grinding

Dry grinding is used in the dry type silica sand ball mill, and no liquid is involved in the process of silica sand treatment. Dry-process silica sand production saves energy, has good sealing performance and no dust pollution. Wet process

More

Silica and Worker Health Silica CDC

2024年2月13日 Silica dust is made up of small particles that can become airborne during work activities with materials that contain silica. Particles that are small enough to be inhaled deep into the lungs are called respirable.

More

Frequently Asked Questions - Silica Safe

For example, blasting, cutting, chipping, drilling and grinding materials that contain silica can result in silica dust that is hazardous for construction workers and others to breathe. ... The “Create-A-Plan” tool on this website provides examples by material and task for controlling dust. Back to the top;

More

Surface modification of silica powder by mild ball milling

2022年11月5日 The dry method can be divided to two coating routes of vapor phase and mechanical mixing technique. The vapor phase technique is carried out by covering material surfaces by a vapor of grafting molecules under high vacuum [13], [14].This technique can form the homogeneous monolayer for the large scale on the surface of materials without any

More

Ductile and brittle mode grinding of fused silica

However, the fused silica is still difficult to ductile grind because of its high brittleness. A creep feed taper grinding method was applied to investigate the relationship between maximum grit depth of cut and surface integrity of fused silica. Ductile

More

Work Safely with Silica

Know the Hazard Workers may be exposed to dangerous levels of silica dust when cutting, drilling, grinding, or otherwise disturbing materials that contain silica. These materials and tasks are common on construction and oil and gas jobs. Breathing that dust can lead to

More

Effects of powder–liquid states on the grinding efficiency of silica ...

2022年8月1日 Grinding is an important and widely applied industrial process for decreasing the size of particles, and it has been most frequently carried out together with liquid medium to improve the efficiency.

More

eLCOSH : Dry Cutting Grinding is Risky Business - Silica Safe

Silica exposure associated with dry cutting and grinding of masonry materials Keywords "silica, silicosis, dry cutting, dry grinding, masonry, construction workers, granite countertop, concrete cutting, stone cutting, tile work, sawing, chipping, tuck pointing, concrete milling, stone polishing, scarifying, stone crushing, needle gunning"

More

(PDF) Chemical Processing of Bauxite: Alumina and Silica Minerals ...

2022年1月23日 Beside the processing behaviour of the main constituents of bauxite such as hydrated alumina and silica minerals, the Chapter covers the impact ... amorphous material shortly after the start of ...

More

Silicon nanoparticles: fabrication, characterization, application and ...

2023年11月23日 Silicon nanoparticles can also be mechanically produced through grinding, either by utilizing a mechanical milling process or grinding bulk silicon in a blender (Fig. 1a) [4, 12]. While the distribution of the fabricated particles tends to be broad, stratification by size within the solution allows for its minimization, enabling the production of silicon nanoparticles ranging

More

SILICA GRINDING - WCIRB California

SILICA GRINDING. Footnote: This classification applies to the crushing or grinding of excavated or quarried materials to produce products that will pass through an 8-mesh screen. If the crushed or ground material is retained on an 8-mesh screen, the crushing or grinding operations shall be classified as 1710, Stone Crushing.

More

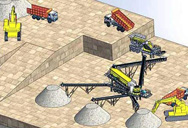

Silica Processing Plant 4 Major Stages to Make Silica

2023年8月10日 Silica sand processing manufacturer Silica sand is a versatile material with a wide range of applications due to its unique properties. After crushing, scrubbing, magnetic separation, and flotation, the purity of silica

More

Working Safely Around Silica - Workplace Material

2023年7月14日 Drilling, crushing, sanding, and grinding can all leave construction workers exposed to silica dust. These tiny particles can easily spread through the air and enter a person’s mouth or nose. Breathing in silica

More

Wet Dry Silica Sand Ball Mill for Silica Sand Grinding

Silica sand ball mill is a professional ball mill equipment for grinding silica sand. In some areas, it is also called silica sand grinding mill or silica sand grinding machine.Silica sand is a chemically stable silicate mineral with

More

Silica - WorkSafeBC

Silica. Silica is one of the ... crushing, drilling, grinding, or blasting concrete or stone releases the dust. As workers breathe in the dust the silica settles in their lungs. For information on protecting workers from harmful exposure to silica ... Eliminating the hazard by substituting a safer process or material, where possible, is the ...

More

Silicon Wafer Material: From Sand to Semiconductors

2024年1月9日 We have traced step-by-step how raw quartz is transformed into pure crystalline silicon wafer material - an essential material underpinning all electronics. We looked at purifying metallurgical grade silicon up to 99.99999% purity, growing large single crystal ingots, slicing wafers, grinding, polishing and rigorous cleaning and inspection processes.

More

Option 3 - Studies and Data on Silica Exposure and the Use of

This study assessed the effectiveness of a commercially available local exhaust ventilation (LEV) system for controlling respirable dust and crystalline silica exposures during concrete grinding activities. Surface grinding was conducted at six commercial building construction sites in Seattle, WA, by cement masons. Concrete - Jackhammering. 2003

More

Experimental study on surface integrity and subsurface ... - Springer

2021年6月12日 The surface quality and subsurface damage (SSD) distribution achieved with a fine-grained grinding wheel under different depth-of-cut and cutting speed is experimentally studied. The ground surface roughness (SR) is investigated via white light interferometry and expressed in terms of four typical roughness values (PV, RMS, Rz, and Ra). The SSD is

More

Temperature field in the crack-free ductile dry grinding of fused ...

Fused silica, i.e., amorphous silicon dioxide, is an excellent ultraviolet transmission window material used in lithography applications, high-peak-power laser fusion facilities and space telescopes because of its high ultraviolet light transmittance, low thermal expansion coefficient and high laser damage threshold [1], [2].However, fused silica is a difficult-to-cut material due

More

Metallography: Part Three - Total Materia

As a result of sectioning and grinding, the material may get cold worked to a considerable depth with a resultant transition zone of deformed material between the surface and the undistorted metal. Course grinding can be accomplished either wet or dry using 80 to 180 grit electrically powered disks or belts, but care must be taken to avoid significant heating of the sample.

More

Characterization of silica sand from grinding and sieving

out a sieving prior to grinding to know the conditions and the graphic behavior of the raw material, this allows to know in which% the silica rock enters and to know the% of fine solids according to the client's specifications and the data sheets. techniques of silica sand as a product (Santos Carpio J.C., 2021).

More