TECHNICAL NOTES 5 CRUSHERS - 911 Metallurgist

Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and gyratory the open-side set (OSS) is specified. This reflects the fact that considerable portions of the

More

Simulation and optimization of gyratory crusher performance

2020年10月1日 On this basis, the impacts of the mantle shaft angle, the concave angle, the eccentric angle, and the mantle shaft speed on the gyratory crusher performance are

More

Metso SUPERIOR® gyratory crushers - Metso

Metso SUPERIOR gyratory crushers are built to help you meet the challenges of highcapacity primary crushing. With thousands of units operating in mines and quarries around the world, Metso has the experience and capabilities to

More

Gyratory Crusher - an overview ScienceDirect Topics

The gyratory crusher shown in Figure 2.6 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower

More

5 Schematic diagram of the longitudinal section of a

Download scientific diagram 5 Schematic diagram of the longitudinal section of a Gyratory crusher together with common design component specifications and labeling.

More

Gyratory Crusher - SpringerLink

2024年1月1日 Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact materials, for

More

Modelling of Gyratory Crusher Liner Wear Using a

2023年10月30日 This study developed a digital sensor and a discrete element modelling (DEM)-coupled methodology to monitor and reconstruct the gyratory crusher concave liner wear pattern. The developed digital sensor was able to

More

Gyratory crusher model and impact parameters related to energy ...

2007年8月1日 The development of a gyratory crusher model was achieved in the following three main stages: mathematical representation and coding of the crushing process; building

More

Types of Crushers Explained: Everything You Need to

2024年4月19日 Nevertheless, gyratory crushers are usually more expensive, need more intricate foundation and have higher operating and maintenance costs as compared to jaw crushers. The decision of a jaw crusher or a gyratory

More

Gyratory VS Jaw Crushers: Advantages Disadvantages

2016年2月28日 No discussion of primary crusher selection would be complete without a comparison of the two leading types: the standard gyratory crusher and the Blake jaw crusher.Although their fields of application overlap to a considerable degree (at least in the realm of primary crushing) there is no real conflict between these two machines; one supplements

More

Gyratory Crushers - 911Metallurgist

2016年2月17日 The below image shows a sectional view of a typical gyratory crusher.This type of machine is, by virtue of chronological priority, known as the “standard” gyratory crusher. Although it incorporates many refinements in

More

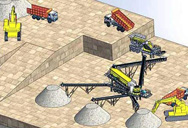

Crushing Plant Design and Layout Considerations - 911 Metallurgist

• Electronic control of crusher discharge opening and feed rate. With adjustment of a crusher’s discharge opening, as the production continues through an on-line coarse size analysis of the crushed product (digital image analyses). Dance, A. 2001) • More attention is being paid to the impact on crushing circuit design caused by variations

More

Types of Crushers: What You Need to Know - HUATAO GROUP

2023年8月2日 The gyratory crusher has a conical shaped head that gyrates inside a bowl-shaped outer shell, while the cone crusher has a mantle and a stationary concave ring. Additionally, gyratory crushers have a higher crushing ratio (meaning that they can crush large material into smaller pieces), a larger feed opening, and a more consistent product size and

More

2. GYRATORY CRUSHERS - 911 Metallurgist

capacity: long-shaft spider-suspended gyratory crusher, fixed-shaft gy- ratory crusher, and short-shaft gearless gyratory crusher. The gyratory crusher, whether used as a primary or secondary. is essentially a gravity-type machine. Material flows vertically from top to bottom. It receives a large coarse feed, usually run-of-mine,

More

Gyratory Crusher vs. Cone Crusher: What's the Difference?

2023年2月23日 A gyratory crusher has a mantle that rotates within a concave bowl, while a cone crusher has a mantle that rotates within a bowl-shaped concave. This design allows for a larger feed size and a higher capacity for both types of crushers, but gyratory crushers are typically designed for high-capacity crushing whereas cone crushers are intended for smaller

More

Gyratory Crusher - an overview ScienceDirect Topics

Gyratory crushers are principally used in surface-crushing plants. The gyratory crusher (Figure 6.5) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeve.The spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within the fixed crushing

More

Gyratory Crusher l Introduce, Working Principle - JXSC Mine

Crusher Machine Advantage. The good effect of fine crushing 1. There are cracks and other weak spots or defects in almost any particle. The double-cavity gyratory crushing, because of the multi-directional pressure on the material, under the interaction of multi-layer material, makes the material easier to be broken from the defect.

More

Gyratory Crusher Gyratory Crusher Manufacturers AGICO

The gyratory crusher, also called primary gyratory crusher, it is mainly used for coarse crushing of various hard materials in the primary stage, crushing various ores by squeezing, ... When the gyratory crusher is in operation, the electric motor drives the eccentric sleeve to rotate through the pulley and bevel gear.

More

Gyratory Crusher - Fote Machinery

A gyratory crusher is a type of large primary crushing equipment used in the mining, aggregates, and construction industries. Its processing capacity is as high as 14,082 t/h, and the feed particle size can reach 1,350 mm. It handles

More

Cone Crushers (Parts of a Cone Crusher) Explained

Crusher Types. There are three common crushers used at mining and processing plants: Gyratory Crushers; Jaw Crushers; Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw

More

Sandvik CG820 Primary Gyratory Crusher For Safe

Sandvik CG820i crusher is built to be robust, reliable and efficient. Connected to SAM by Sandvik, ... Our range stationary gyratory crushers Stationary gyratory crushers. CG850i Capacity (by hour) 3,800 - 8,250 mtph (4,180 - 9,075 stph)

More

Fault Diagnosis of the Gyratory Crusher Based on Fast Entropy ...

2021年6月25日 PDF Gyratory crusher is a kind of commonly used mining machinery. Because of its heavy workload and complex working environment, it is prone to... Find, read and cite all the research you need ...

More

Analysis and optimization of vibration characteristics of gyratory ...

2024年10月1日 In the mineral processing industry, comminution technology plays a crucial role in facilitating the efficient extraction of mineral resources (Campos et al., 2019, Zhou et al., 2019, Al-Khasawneh, 2021, de Oliveira et al., 2021).The use of a gyratory crusher, a robust crushing device widely employed in the fields of mining, metallurgy, construction, and chemical

More

Gyratory Crusher Pro - FLSmidth

Our Gyratory Crusher Pro offers our customers high-performance crushing operations under toughest conditions from -40°C to 50°C - whether it is the heat of the Australian summer or the cold of the Norwegian winter.. Built for ultimate performance and easy maintenance, this hard rock crusher excels at the crushing of medium hard to hard rock and ore in semi-mobile and

More

Gyratory crusher model and impact parameters related to

8 =[ ] ), = = and , = = (The = (= = = (= = =, , = =

More

Gyratory crusher (adapted from ThyssenKrupp, 2005).

Download scientific diagram — Gyratory crusher (adapted from ThyssenKrupp, 2005). from publication: A Gyratory Crusher Model and Impact Parameters Related to Energy Consumption The objective ...

More

Compare Gyratory Crusher vs Jaw Crusher - 911Metallurgist

2015年7月18日 Primary crushing is the first of these stages. Generally speaking there are two types of primary crushers, lets compare them: GYRATORY CRUSHER or a JAW CRUSHER. Although they don’t look anything like they do have similarities that put them into the same class of crusher. Their CRUSHING SPEEDS are the same, 100 to 200 revolutions per minute.

More

Stationary Semi-mobile crushing solutions Primary gyratory

gyratory that provides a low cost per ton through energy efficiency, durability and optimized crusher performance. Crusher range Metso offers a comprehensive range of SUPERIOR® primary gyratory crushers. Crushers are available in models with capacities ranging from 2010 to 8890 mtph (2200 - 9800 stph) and feed

More