Tripper Conveyor Belt Conveying System

Belt Trippers are short belt conveyors that can be positioned at different points along a main belt conveyor to “trip” or divert the flow of bulk materials off through a chute. Bulk materials discharge off the Belt Tripper to another belt conveyor, to storage or to processing.

More

CHW53197 Eaton Crouse-Hinds series AFU conveyor belt trip

Eaton Crouse-Hinds series AFU conveyor belt trip switch, Double end. Contact me about this product. Download complete specs. General specifications. Certifications and compliances. Product specifications.

More

3 Basic Conveyor Belt Tracking Rules To Follow

Tracking rule 1. The belt tracks to the side with the least tension. Tracking effect of cylindrical-conical or radially crowned pulleys. Fabric belt conveyors are

More

Conveyor belt - Wikipedia

Today there are different types of conveyor belts that have been created for conveying different kinds of material available in PVC and rubber materials. Material flowing over the belt may be weighed in transit using a beltweigher. Belts with regularly spaced partitions, known as elevator belts, are used for transporting loose materials up steep inclines. Belt Conveyors are used in sel

More

The Complete Guide to Industrial Conveyor Selection,

FEECO offers three main belt conveyor types that cover most handling needs: Troughing Conveyors. Steep Incline Conveyors. Reversing Shuttle Conveyors. It’s important to note that bucket elevators complement industrial conveyor

More

IEC Conveyor Standard Belt Trip Switch

IEC Conveyor Standard Belt Trip Switch Author: E7750886 Created Date: 2/13/2018 12:10:53 PM ...

More

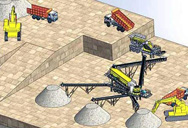

How is a tripper conveyor working? - SKE Industries

2021年4月15日 A tripper conveyor is a form of conveyor belt used in construction, mining, and other large-scale earth-moving businesses. They are also known as tiered or stepped conveyors, and the term "tripper" is a colloquialism that formed after they came into widespread use.

More

IEC AFU Conveyor Belt Trip Switches Crouse-Hinds series Eaton

IEC AFU conveyor belt trip switches from Eaton's Crouse-Hinds Division provide an emergency or normal STOP switch for conveyor lines, cranes, unloaders and bulk handling systems. They are installed in the control circuit of magnetic motor starters to shut down motor-driven

More

Belt Conveyors: Components, Types, Design, and

A belt conveyor is a system designed to transport or move items such as materials, goods, or even people from one point to another. Unlike other conveying methods that use chains, spirals, or hydraulics, belt conveyors

More

IEC Conveyor Standard Belt Trip Switch

0qfsbujpo 7kh frqyh\ru ehow wuls vzlwfkhv duh xvhg lq frqmxqfwlrq zlwk rwkhu dffhvvrulhv dorqj vlgh frqyh\ru v\vwhpv wr surylgh d idlo vdih vwrs phfkdqlvp iru hphujhqflhv 7kh\ duh lqvwdoohg dorqj wkh hqwluh

More

CT Systems Conveyor Trip Switches

Take a look at our range of Conveyor Trip Switches +27 (0) 11 845 3258. 45 Lake Avenue, Benoni, 1500, ... Products. Trip Switches; Belt Protection Unit; Systems; Hardware Accessories; Spares; Forms and Drawings; Support; Contact Us; By closing this message, you consent to our cookies on this device in accordance with our cookie policy unless ...

More

What’s a Conveyor Belt: Hazards and Safety Measures

2024年9月22日 2. Specific Conveyor Types and Their Hazards a. Belt Conveyors. Hazards: Drive Mechanisms: The moving belt interacts with drive components, creating nip and shear points where severe injuries can occur. Take-Up and Discharge Ends: Areas where the belt tension is adjusted or where materials are loaded/unloaded can pose significant risks. Pulley

More

CHW53197 Eaton Crouse-Hinds series AFU conveyor belt trip

IEC AFU Conveyor Belt Trip Switches. CHW53197 Overview Specifications Resources. How to buy Locate a channel partner; Questions before you buy; Back to search. Download Zoom. Download Zoom. CHW53197 Eaton Crouse-Hinds series

More

Home - Conveyor Supplies Africa

Quality Assurance: Our conveyor belts are manufactured to the highest quality standards, ensuring reliability and longevity.; Customization Options: We offer customization services to meet your specific requirements, including belt width, length, and material composition.; Expert Support: Our team of experienced professionals is dedicated to providing expert advice and

More

Engineering Plastics Conveyor Component Suppliers and

IRP Engineering Plastics was founded in 1987 and has since been the industry leader in the supply of quality locally manufactured Conveyor Components, Modular Belts, SlatBand Chains, Sprockets/Idlers and bespoke CNC machined products for the food, beverage and packaging industries to date.

More

Common Belt Conveyor Problems Solutions

2024年6月3日 Common belt conveyor problems include misalignment, belt slippage, and material spillage, which are often caused by improper installation, lack of maintenance, and wear and tear over time. This blog aims to provide comprehensive solutions to these conveyor belt problems through a detailed, downloadable PDF guide.

More

Cleatrac® Transfer Belt System Ashworth Conveyor Belts

Exception: If the application has a conveyor end-to-end distance of 10' (3 m) or less and the belt fits loosely around the conveyor, the minimum nose roll diameter may be decreased as follows: Mesh Minimum Diameter in (mm) CTB 18-16-1414 1 (25.4) ...

More

Safe and reliable conveyor belt control, always ready for action

IEC Conveyor Switches Safe and reliable conveyor belt control, always ready for action IEC AFU Conveyor Belt Trip Switch General Operation: The conveyor trip switch facilitates stopping the conveyor, in the event of an emergency from any point along the entire length of the conveyor, giving safety to physical harm and mechanical damage.

More

3 Basic Conveyor Belt Tracking Rules To Follow

Conveyor belts are frequently blamed for belt tracking problems and in most cases this is unjustified. The failure cause is usually to be found in the installation itself and may be the result of poorly adjusted pulleys and rollers, incorrect application of belt tracking measures or

More

Conveyor Safety Switches for Material Handling

Pull cord switch is mounted on the walkway side of the conveyor belt, preferably at about every 30 ... (No. Of switches per conveyor, conveyor layout etc). For more details refer our catalogue on: Trip Indicator. Hermetically sealed reed

More

Pull Switch Trip Identification and Prestart Warning System ...

conveyor belt at 100m intervals. Each pull switch is interlinked via a pull-cable on the one side of the conveyor belt. Pull switches mounted on the opposite side of the conveyor belt are interlinked via steel wire rope. Each trip switch also sounds an audible alarm via two piezo-resistive buzzers,

More

Different Types of Conveyor Belts and Their Uses

2023年4月6日 A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system is one of many types of conveyor systems. A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with a closed loop of carrying medium—the conveyor belt—that rotates about them.

More

Belt Conveyors: Components, Types, Design, and Applications

2023年11月2日 Multi-chapter guide to belt conveyors describing: what they are, types, applications and benefits of belt conveyors ... Conveyors used in industrial settings include tripping mechanisms such as trip cords along the sides of the conveyor with safety start-stop buttons to ensure operators can shut down the conveyor with immediate ...

More

Safe and reliable conveyor belt stopping, where and whenever it

1.1 Conveyor standard/slack belt trip switch General operation The conveyor trip switch facilitates stopping the conveyor, in the event of an emergency from any point along the entire length of the conveyor, giving safety to physical harm and mechanical damage. Standard Belt Operation The conveyor trip switch, is a safety switch that has a pre-

More

Conveyor Belt RIP Switches Safe-T-RIP - Power Control Products

A Conveyor Belt Rip or Tear Switch, like the Safe-T-RIP range, is a critical device that detects any damage to the belt, thereby preventing further destruction, minimizing downtime, and preserving the efficiency of the conveyor system. These switches are predominantly used in

More

GUIDELINE Safety Around Belt Conveyors

Safety Around Belt Conveyors CMA MS01 Rev04/2016 6 Belt control initiates a run command to the drive controller. Sometimes the belt control issues a running reference speed to the drive controller. For stopping, the belt control simply removes the positive run signal to the drive controller or initiates a ramped stop command. Stop/Start

More

Improve Conveyor Safety with Emergency Stop Switches - Martin

In case of emergency, pulling the rope will interrupt the conveyor's power, halting the belt. In 1995, the U.S. Mine Safety and Health Administration conducted a study of 1100 conveyor systems, revealing a 2 percent failure rate for emergency stop switches.

More

Eaton – IEC AFU Conveyor Belt Trip Switches

IEC AFU conveyor belt trip switches from Eaton's Crouse-Hinds Division provide an emergency or normal STOP switch for conveyor lines, cranes, unloaders and bulk handling systems. They are installed in the control circuit of magnetic motor starters to shut down motor-driven conveyors or other machinery when switch is actuated. IEC AFU switches are certified for Zone 21 and

More