Gypsum Powder Processing

With the in-depth application of gypsum grinding equipment, the application value of gypsum powder continues to expand. Among them, the application value of building gypsum production line and desulfurization gypsum production line.

More

YGM Raymond Mill - Baichy

YGM raymond roller mill is new type high pressure grinding mill used for fine powder processing of more than 500 kinds of materials, such as limestone, gypsum, kaolin, clay, talc, feldspar, talc, barite. The fineness is between 80

More

Calcining processes for natural and synthetic gypsum

The roller mill is a short-time calcining system. Both natural gypsum and mixtures of natural and synthetic raw materials can be ground, dried, calcined and classified in this kind of mill. Bundling several process steps results in highly

More

Gypsum Powder Manufacturing Gypsum Powder

Gypsum powder-making process. According to the process requirements, the construction gypsum production line is usually divided into five parts, including crushing system, storage conveying system, grinding system, calcining

More

GLOBAL GYPSUM: GRINDING - Gebr. Pfeiffer

of manufacturing vertical roller mills (VRMs) for the gypsum sector, supplying its fi rst mills to the sector in 1963. It is one of the technical leaders in this fi eld, introducing its gypsum grinding and calcining mills in the late 1990s. Th ere are 49 MPS VRMs references for gypsum grinding and drying, plus 30 MPS VRMs for gypsum calcining.

More

Gypsum Powder Process Technology, Gypsum Grinding Mill

Powder process technology: Gypsum is monoclinic system, with a high degree of cleavage, easily split into thin slices. When gypsum is heated to 100 ~ 200 ° C, it loses some crystal wate, and hemihydrate gypsum appears. α-hemihydrate gypsum crystal is good and solid; β-hemihydrate gypsum is flaky and cracked, with small crystal and high specific surface area than the α

More

Cement Roller Press, Roller Press In Cement Plant HPGR Crusher

As a leading cement grinding plant manufacturer in China, we offer roller press in cement plant, roller press cement mill, high pressure grinding roller, Get your free quote now!. Skip to content +86 13683722138

More

News - Application of HLMX Ultrafine Vertical Roller Mill for Non ...

At present, the market demand for non-mineral powder is increasingly strong, and the annual average growth rate of consumption of heavy calcium is nearly 9.5%. It is predicted that the annual demand for non-metallic mineral powder will still maintain a high growth rate in the next 10 years. In the pursuit of stable product quality and uniform particle size distribution, the market

More

Gypsum Powder Grinding And Processing Plant Equipment

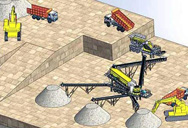

2024年1月23日 Step 3: Stone Powder Grading. The gypsum powder enters the powder screen machine for classification. The unqualified gypsum powder goes back to the Raymond mill for secondary grinding. Step 4: Calcination of stone powder. Gypsum powder meets the fineness requirement and enters a fluidized bed furnace for calcination treatment.

More

11.16 Gypsum Manufacturing - US EPA

Applies to both heated and unheated roller mills. j References 11-14. Factor is for combined emissions from roller mills and kettle calciners, based on the sum of the roller mill and kettle calciner output rates. k References 4-5,11,13-14. Emission factors based on the kettle and the hot pit do not apply to batch kettle calciners. mReferences 3 ...

More

Cement Production Demystified: Step-by-Step Process and

Once the clinker is produced in the kiln, it is cooled and then ground into a fine powder using a combination of ball mills and vertical roller mills. During the milling process, gypsum is typically added to the clinker powder to control the setting time of the resulting cement.

More

Gypsum powder processing: The role of grinding mills

One of the key steps in the gypsum powder production process is the use of grinding mills to convert gypsum ore into fine powder. The Necessity of Grinding Mills in Gypsum Powder Processing: Gypsum ore, extracted from quarries, often contains impurities and needs to be processed to meet the quality standards required for different applications.

More

Gypsum powder mill plant

Gypsum powder production line is the natural dihydrous gypsum ore (gypsum) or industrial by-product gypsum (desulfurized gypsum, phosphogypsum, etc.) through grinding mill and after a certain temperature heating calcination, so that the dihydrous gypsum dehydration decomposition, the generation of β semi-hydrous gypsum (CaSO4 1/2H2O) as the main component of the

More

Gypsum powder making production line, Gypsum powder processing plant

In the gypsum powder grinding plant, gypsum grinding equipment is used for gypsum pulverizing to produce gypsum powder from crushed gypsum rock. CLIRIK Machinery can supply the state-of-the-art manufacturing facility which is fitted for gypsum grinding process, to produce a wide range of micron size of chemical purity, outstanding brightness and controlled particle size

More

News - Advantages Of Gypsum Vertical Roller Mill As Production ...

Building gypsum is a product that uses gypsum as raw material and is ground after calcination, also known asβType I hemihydrate gypsum is the main raw material for gypsum products such as gypsum plasterboard, fiber gypsum board and gypsum decorative board. The main machine in the production equipment of building gypsum powder is gypsum grinding mill equipment.

More

Gypsum mill for all requirements Gebr. Pfeiffer

Coarse natural gypsum or mixtures of such gypsum with FGD gypsum are ground, dried, calcined, and classified in the Pfeiffer vertical roller mill. To be noted that up to 20% of recycling material may be added if required. Product fineness and product properties can be adjusted within wide limits (0.063 to 0.5 mm).

More

(PDF) Performance Evaluation of Vertical Roller Mill in

2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in ... Gypsum (t/h) 4.83 . 4.74 ... The grinding process in such mills occurs ...

More

Gypsum Powder Making Production Line Manufacturer

Zenith has researched painstakingly on mill making technology for more than 20 years. According to the characteristics of gypsum material, Zenith utilizes Vertical Roller Mill, fluidized bed combustion boiler for the Gypsum Powder Line, and makes the automatic production into reality by adopting the DCS Automatic Control System.

More

MPS vertical roller mill for gypsum grinding - Gebr. Pfeiffer

Since 1991 a vertical roller mill of the type MPS 125 A has been operating in the Hartershofen works taken over by Siniat. This mill was used for grinding and processing natural gypsum, flue gas desulfurization gypsum, and recycled material to obtain the basic material needed for the production of plasterboard products

More

Slag Grinding Plant GGBS Plant Slag Mill, Slag Grinding Mill

In addition to the vertical slag mill, other types of cement mill that can grind slag powder include: cement ball mill, pre-grinding cement roller press, and cement roller press for final grinding. For slag grinding plant, ball mill generally causes problems of dust accumulation, low grinding efficiency and high grinding temperature.

More

The boiling furnace for gypsum industry, gypsum powder

2019年5月21日 1 The Boiling Furnace For Gypsum Industry Shanghai Clirik Machinery Co.,Ltd Devoted to the powder process area ShanghaiClirik M achinery ... 3 Workflow for the calcined gypsum plant The nature gypsum ore is crushed into ... the gypsum granular are fed into roller mill to grind into 100-200 mesh powder. Then flow into the ...

More

Roller Mill - SpringerLink

2024年1月1日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces ... caustic-burned magnesia powder, kaolin, wollastonite, gypsum, lime, bentonite ... which is the product. Moisture containing materials are dried in the process of contacting with hot airflow. By adjusting the hot ...

More