Escondida - BHP

Escondida is a copper porphyry deposit located in the Atacama Desert in Northern Chile, 170km south-east of Antofagasta. The name Escondida means 'hidden’ in Spanish. It derives from the main orebody which doesn't outcrop on

More

Minera Escondida - Wikipedia

Minera Escondida (which means 'hidden' in Spanish) is a mining company that operates two open pit copper mines in the Atacama Desert, 170 km southeast of Antofagasta in northern Chile. It is currently the highest producing copper mine in the world. Its 2007 production of 1.483 million tons of the metal was worth US$10.12 billion, mainly as metal in concentrate, but some as cathode, and w

More

CH Machine EDM Services Experts in Precision 4

Welcome to CH Machine, your World-Class Manufacturing Partner located in Escondido, CA. We are an AS9100:2016 Rev. D certified and ITAR registered precision manufacturing facility specializing in full-service Milling, Turning,

More

Escondida site tour - BHP

Mineral Resource information for the Escondida district includes Escondida, Pampa Escondida, PintaVerde and Chimborazo resources as disclosed in the BHP Billiton 2012 Annual Report

More

100927 Minera Escondida - BHP

Escondida – key messages Simple and effective organisation led by an experienced team Zero Harm is non-negotiable The operation is performing strongly following the successful SAG mill

More

Escondida - Mitsubishi Corporation

Escondida is the largest copper mine in the world by production. The first shipment of copper concentrate from Escondida took place in 1990. Following subsequent expansion phases, Escondida produces over 1.0 million tons per

More

Escondida - Wikipedia

Escondida is a copper mine at 3,100 metres (10,200 ft) elevation in the Atacama Desert in Antofagasta Region, Chile. [1]

More

Continuous Improvements in Mill Relining at Escondida

2019年9月23日 In 2014, Escondida engaged RME to complete a MILL RELINE DIRECTOR (MRD) Filmed Study to investigate ways of improving concentrator performance and

More

Overflow VS Grate Discharge Ball or Mill – Why

2015年6月25日 The cost of a ball mill conversion from overflow to grate discharge is ‘fairly’ affordable at $65,000 for a 13′ x 15′ mill. This is only for the discharge head, grates and pulp filters (rubber). A comparison in laboratory

More

Converting a ball mill from overflow to grate

2020年6月23日 Converting a mill from an overflow to a grate discharge arrangement leads to an increased power draw. This happens because the installation of the grate discharge arrangement enables the mill to run with a

More

' SAG mill discharge, mill head removed for clarity

The coupled DEM + SPH has been used for the prediction of the slurry flow within a SAG mill grinding chamber, flow through the grate and discharge flow along the pulp lifters [36 , 37] .

More

Slurry flow in mills: grate-only discharge mechanism (Part-1)

2003年7月1日 The flow capacity of a grate discharge mill is controlled both by the grate design and and the mill operating conditions. The effect of each design and operating variable is therefore discussed independently in the following sections. 3.1. Flowrate-mill hold-up

More

Updated magnetic separation techniques to improve grinding

2004年11月1日 The SAG mill oversize reporting to the pebble crusher is conveyed under a suspended electromagnet. The magnet collects grinding media and removes it prior to the crusher. (4) A Trunnion Magnet is mounted at the ball mill discharge. The Trunnion Magnet is replaces the trommel screen and removes grinding ball fragments directly from the mill ...

More

Gearless Mill Drive Protection Improvements and Its Behaviour at

Gearless Mill Drive Protection Improvements and Its Behavior at Minera Escondida Ltda. Luis Nieto C. Markus Ahrens Gerencia Mantenimiento Procesos Minera Escondida Ltda, MEL Operated by BHPBilliton Antofagasta, Chile Luis.a.nieto@bhpbilliton Engineering Drives ABB Switzerland Ltd Baden-Dättwil, Switzerland [email protected] Abstract—A

More

Grinding Plant Design AND Layout Considerations - Studocu

standby pump and distributor will be installed at Escondida IV. Normally the discharge from the SAG mill is “lubricated” by the substantially higher volume of much finer ball mill slurry. Tlus “lubrication” is lost when pumping minus %,, SAG mill product alone, resulting in increased pump wear. SAG DISCHARGE SIZING AND OVERSIZE ...

More

Peripheral Discharge Ball Mills -Theory and Practice

2016年3月14日 The principal function of the grate is to retain the ball charge in the mill, while permitting a peripheral discharge. The efficiency of the classifier, when a ball-mill is run in closed circuit, directly affects both tonnage and fineness. This will be discussed under capacity. Conditions Affecting Ball-Mill Capacity

More

Grate Discharge Mill Escondida

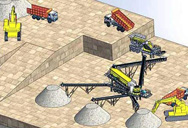

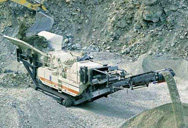

Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns.; The Center-Periphery Discharge mill has feed reporting from both

More

Polydeck#39;s Discharge Screen Solution for Mill and scrubber ...

If your mill or scrubber discharge screens are prone to inefficient classification and frequent maintenance downtime, then it may be time to consider a better alternative.

More

Reinforcement learning based ball mill discharge size distribution ...

Abstract: The particle size distribution of ball mill grinding products is an important production index of the grinding operation, and due to its multivariate strong coupling and nonlinearity in the operation process, it leads to difficulties in achieving optimal control of the discharge particle size distribution. To this end, a reinforcement learning-based optimal control method is proposed ...

More

Overflow vs. Grate Discharge Ball Mills: What’s the Difference?

2024年8月12日 Overflow ball mills are designed so that the ground product overflows out of the mill. The overflow expels the ground material because of the slurry flow out of the mill. On the other hand, grate discharge ball mills have a grate wall at the discharge end, which holds the larger particles while the fine slurry is allowed to pass through.

More

Rod Mills: Efficient Grinding Solutions for Mining

2016年6月1日 Mill discharge is generally less than 5% + 4 mesh in wet open circuit operations, for dry grinding work reduce the capacities indicated by approximately 30% to 50%. Rod Mill Working Principle Components. A Rod

More

Major Mines Projects Escondida Mine

The Escondida cluster is formed by the Escondida (including Escondida Este) and Escondida Norte - Zaldívar porphyry copper deposits. The latter corresponds to the same ore body mined by two different companies and operations. Additionally, the porphyry copper deposits of Chimborazo and Pampa Escondida, as well as Pinta Verde, have been recognised.

More

Comminution Circuits for Gold Ore Processing - ScienceDirect

2016年1月1日 Many large mills around the world (Esperanza with a 12.8 m mill, Cadia and Collahuasi with 12.2-m mills, and Antimina, Escondida Ph IV, ... For those circuits treating ball-mill discharge, a sluice can often be arranged to provide some preconcentration for

More

A REVIEW ON THE DEVELOPMENT OF PALM OIL MILL EFFLUENT

Raw palm oil mill effluent (POME) contains high amount of organic materials and residual oil that will impose high biological oxygen demand (BOD) and chemical oxygen demand (COD). It has a high acidic

More

Escondida BHP presentó plan de crecimiento con anuncio de

2023年3月24日 El jueves 23 de marzo Escondida BHP presentó su plan de crecimiento para las próximas décadas, en una actividad pública liderada por el presidente de la compañía, James Whittaker, la cual contó con la participación de autoridades regionales y representantes de la comunidad de Antofagasta.

More

Machining Equipment List Including CNC Mill, EDM Drill More

Electric Discharge Machining (EDM) Wire EDM; Sinker EDM; CNC Milling. 4 Axis Milling; 5 Axis ... HAAS Mini-Mill: 16"x12"x10" 6,000 rpm : 1: 4: FANUC ROBODRILL: x19.7" y14.9" z11.8" 12,000 rpm: ... (Receiving) Escondido, California 92029-1934. Quick Links Explore all our Capabilities Equipment List AS9100:2016 Rev. D Certification ITAR ...

More

The Evolution of Grinding Mill Power Models Mining,

2019年1月30日 Mill power models have been used in a variety of ways in industrial practice since power directly equates to throughput and fineness of ground product. We first start with Hogg-Fuerstenau Power Model and show how this model successfully predicted the power draw of many grinding mills in several mining operations. Then, we show how this model was on the

More

Combined DEM and SPH simulation of overflow ball mill discharge

2017年7月1日 A trommel is a rotary cylindrical structure that is rigidly attached to the discharge end of a mill. The intended operation of the trommel is shown schematically in Fig. 1.It contains moulded screen panels or wire mesh and can have different aperture configurations in each axial section depending on the intended duty.

More