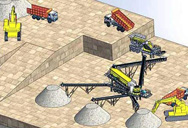

Crushing Plant Design and Layout Considerations - 911 Metallurgist

In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum. This paper addresses the critical design parameters as well as the consideration of ore

More

Comminution and classification technologies of iron ore

2022年1月1日 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct

More

Crushing and Screening Handbook - AusIMM

Track-mounted crushing plants – fully mo-bile jaw, cone or impact crushing plants, with or without screens, and equipped with open or closed circuit and discharge conveyors. Easily

More

Schematic description of the crushing plant, (1)

In this study, the DEM (Discrete element method) bonded particle model is constructed to simulate the crushing process of iron ore based on the Apollonian sphere packing (ASP) method in a...

More

Crushing Plant Flowsheet Design-Layout

2016年3月11日 Table of Contents. Crusher Plant Layout. Crushing. Screening. In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made

More

Crushing characteristics and performance evaluation of iron ore in

2023年12月1日 In this paper, the crushing process of spherical iron ore particles in a cone crusher has been numerically reproduced by DEM. The effects of operation parameters

More

(PDF) Crushing and Screening Handbook - Academia

This paper assesses a number of factors affecting the performance of the crushing plant by addressing the critical design parameters and consideration of ore characteristics, operability and maintainability. Due to the fact that ore

More

Iron ore sintering - ScienceDirect

2022年1月1日 The sintering process begins with preparation of a sinter mixture consisting of iron ore fines, fluxes, solid fuel (called bonding agents in Japan) such as coke breeze, and

More

Crushing Screening Plant Design Factors

2016年4月14日 Crushing Plant Design and Layout Considerations SUMMARY. In all of the above Crushing Circuit flowsheets we recommend a magnetic head pulley or a permanent magnet ahead of the secondary crusher to remove

More

iron ore crusher plant design step by step - CM Mining Machinery

2023年12月16日 The design of an iron ore crusher plant is a complex process that requires careful consideration of all of the factors involved. By following the steps outlined above, you

More

Mass balance control of crushing circuits - Tampereen

Keywords: Crushing, Mass balance control, Limiting control, Dynamic modeling, Sensor fusion 1. Introduction Crushing is an essential multi-stage processing step in the production of minerals, metals, aggregates, and cement. A crushing circuit comprises a combination of unit operations for crushing, screening, conveying, feeding, and ...

More

Crushing Plant Flowsheet Design-Layout

2016年3月11日 In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, ... Most crushing plants are now designed on the lines shown in Fig. 1, which is

More

Tata Steel commissions iron ore processing plant in

2021年11月24日 Tata Steel has set up 8 million tonne per annum crushing and washing plant at its captive Khondbond Iron and Manganese Mine near Joda in Keonjhar district of Odisha.

More

Intelligent dry fog dust suppression system: an efficient

2020年11月21日 The system has been implemented in an iron ore crushing and screening plant in India, and its efficacy has been evaluated for controlling dust emission. The installed dry fog system reduced dust concentration to 0.10–0.17 mg m −3 from the prevailing dust concentration of 0.62–1.73 mg m −3 in work zone areas, ...

More

The six main steps of iron ore processing - Multotec

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing.

More

Iron Ore Pelletizing Process: An Overview - IntechOpen

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking. This chapter

More

Iron Ore - Geoscience Australia

2023年12月19日 Iron (Fe) is a metallic element that constitutes 5.6% by weight of the Earth's crust and is the fourth most abundant element in the crust. Iron ores are rocks from which metallic iron can be economically extracted. The principal iron ores contain hematite (Fe 2 O 3) and magnetite (Fe 3 O 4). Hematite is an iron oxide mineral.

More

Iron Ore production in the Pilbara

where there are long distances between the pits and process plants. Process Processing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products. This is

More

Beneficiation of Iron Ores - IspatGuru

2014年4月3日 Fig 3 Types of processing ores. The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore. The wet process consists of multi-stage crushing followed by different stages of washing in the form of scrubbing and / or screening, and classification etc., but the advantage is only partial removal of adhered alumina

More

Iron ore mining and dressing - tec-science

2018年6月21日 Regions in which iron ore has formed over millions of years (e.g. through volcanism) and can be mined economically are also referred to as iron ore deposits. Especially many ore deposits can be found in countries such as China, Australia, Brazil, India and Russia. These countries account for around 85 % of the total global iron ore mining volume.

More

organizational structure of crushing and aggregate plant

Aggregate Rock Crushing Operations Policy Manual. Aggregate and rock crushing operations Rule 401 Ringelmann Chart: The rock crushing operation SHALL OPERATE WHENEVER THE AGGREGATE PLANT IS IN OPERATION. » More detailed! Crushing Plant Design and Layout Considerations. crushing plant’s structure and enclosure can represent the largest

More

iron ore crusher plant design step by step - CM Mining Machinery

2023年12月16日 The first step in designing an iron ore crusher plant is to define the project requirements. This includes the following: The type of iron ore that will be processed; The desired output of the plant; The required particle size of the crushed iron ore; The budget for the project; Step 2:Select the crushing equipment

More

ore crusher structure

Iron Ore Handling Plant Structure Details Brics Crushing Plant. Iron Ore Handling Plant Structure Details Brics Crushing Plant Iron Ore Processing for the Blast Furnace A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a pellet ...

More

Schematic description of the crushing plant, (1) primary crusher,

In this study, the DEM (Discrete element method) bonded particle model is constructed to simulate the crushing process of iron ore based on the Apollonian sphere packing (ASP) method in a cone ...

More

Effect of Iron Ore Particle Assimilation on Sinter Structure - J

During iron ore sintering, a packed bed of uniformly dis-tributed granules—composed of a range of iron ore types, fluxes, fuel, return sinter fines and plant dusts—is trans-formed into porous sintered particles of irregular shape. The yield of the sinter machine (i.e. the percentage sinter

More

Modeling and simulation for design of iron ore processing plant

2014年10月1日 Feed to the plant is Hematite iron ore from a deposit located in Eastern India. Major processes in plant include multi-stage crushing, screening, grinding, classification, gravity and magnetic ...

More

Plant Mining Organization Chart Crusher Mills, Cone Crusher,

2011年12月26日 iron ore mining organization chart sample – Crusherb2b. iron ore mining organization chart sample. China Shanghai liming Machinery Suppliers types of quarry crushing plant,mining Equipment,Grinding mill,making Silica sand

More

Selection Of Lithium Ore Processing Plant Equipment

2024年4月8日 After lithium crushing, classification, and separation. It will exert good application value. A jaw crusher is an essential crushing equipment in a lithium processing plant. It has strong adaptability and is not affected by the hardness, humidity, structure, and other characteristics of the original ore during the crushing process.

More

What Are The Equipment Of Chrome Ore Washing Plant?

2024年10月25日 Drum magnetic separator. The drum magnetic separator is used to separate iron-containing impurities below 3 mm and can automatically remove magnetic contaminants that are difficult to separate from non-magnetic materials. The material is evenly fed to the magnetic field area on the upper part of the rotating drum through an electromagnetic vibrating feeder.

More