Technical Details of the Primary Jaw Crusher – stone cruxder

One of the key technical aspects of the primary jaw crusher is its crushing mechanism. The crusher is equipped with a fixed jaw and a moving jaw, which are made of high-quality manganese steel. The fixed jaw is mounted on a frame, while the moving jaw is attached to

More

Industrial Solutions Jaw crushers - ThyssenKrupp

primary crushers to crush blasted rockpile, which may have edge lengths of over 2,000 mm depending on the blasting method, in preparation for finish crushing or conveying. For these

More

SANDVIK JAW CRUSHER SERIES - Sandvik Mining and Rock

Sandvik’s top-of-the-line CJ-type jaw crushers are specifically built for your primary applications where resizing is the key objective. They allow the material to be processed within your

More

TECHNICAL SPECIFICATIONS SANDVIK QJ341+ JAW CRUSHER - SRP

With its large feed opening and unique crushing geometry our QJ341+ will offer you a reliable, durable and high performance mobile jaw crusher like no other. FEATURES INCLUDE: –

More

Primary Jaw Crusher – Everything You Need to Know

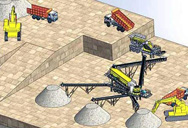

2023年2月28日 A primary jaw crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. It is used in many industries, including mining, construction, and demolition, to crush materials such as

More

TECHNICAL SPECIFICATIONS SANDVIK QJ241 - SRP

leading series of jaw crushers from Sandvik. Specifically designed for the smaller operation, it can achieve impressive rates of production with excellent reduction ratios. The machine is

More

Jaw Crushers JW Series

The JW Series of single toggle jaw crushers is designed with a tight crushing chamber nip angle and an aggressive crushing stroke to maximize productivity. The accompanying table gives

More

Jaw Crushers – MEKA

Jaw crushers are used as the primary crushers in the first stage of a crushing process for the breaking of large-sized rocks, while jaw crushers with smaller mouth openings are used to break smaller ores into finer sizes. Two basic jaw

More

Nordberg® C Series™ jaw crushers Proven reliability and ... - Metso

Nordberg® C Series™ jaw crushers are designed to handle the toughest feed materials in the primary crushing stage. They have proven their performance in at least 10,000 reference

More

Nordberg C Series jaw crushers - International Crusher Solutions

The world’s favourite jaw crusher. jaw crushers since the 1920s. Today the Nordberg C Series is indisputably the w. rld’s favourite jaw crusher. Where cost-eficient primary reduc-tion of

More

What is a Primary Crusher? - Machinery Partner

Primary jaw crusher and secondary impact crusher working together in a plant set-up. The most common primary crusher is a jaw crusher, but, there are many other types including gyratory and cone crushers. We will talk about

More

Primary Crusher vs. Secondary Crusher:

2023年2月28日 The primary crusher’s function is to reduce the size of the rock or stone for easier handling and transportation. The primary crusher is usually a jaw crusher or a gyratory crusher, which operates by compressing the

More

Construction, Working and Maintenance of Crushers for Crushing

3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low ... Gyratory crusher is generally used as a primary crusher. The crusher is popular due to its ... (concaves). Construction detail and working of the crusher is as under. The main shaft of the crusher is journaled in the spider bearing and in the eccentric bearing

More

What Are The Parts Of A Jaw Crusher? - Caldas Engineering and ...

The structural backbone of a jaw crusher comprises two main parts: the stationary and the movable jaw frames, constructed mainly of high-quality steel or iron. The stationary or fixed jaw forms the crusher’s side that does not move. The other, the swing jaw, moves back and forth against the fixed jaw, crushing the material between.

More

Primary Crushing - 911Metallurgist

2016年2月26日 For such rock or ore our choice of a primary crusher is restricted to the gyratory and jaw types except, again, for the occasional “specialty” application where economy in maintenance may be sacrificed for other considerations such as lower first cost, or space restrictions. Crusher Capacity Factor

More

Understanding Types of Jaw Crusher: A Comprehensive Guide

Exploring types of jaw crusher for mineral processing solutions. ... it’s all about finessing materials that have already been roughed up by a primary crusher. This time, the pieces coming in are usually between 100 and 250 mm (4 to 10 inches), and the aim is to get ... For pricing details of various jaw crusher types, read Jaw Crusher ...

More

Jaw Crusher (PE Series Primary Crusher) GTEK

Working Principle. Jaw crushers reduce rocks or ore by means of compression.This mechanical pressure is achieved by the crusher's two jaw dies/ jaw plates, one of which is stationary and the other is movable.These two vertical manganese jaw dies create a V-shaped cavity called the crushing chamber.The material is fed into the top of and the movable jaw compresses material

More

Nordberg® C Series™ jaw crushers Proven reliability and ... - Metso

lasting performance. Metso jaw die fixing components are extremely durable and can be quickly replaced, reducing wear part-related costs even further. Metso Outotec also develops custom jaws for special applications. Special cheek plates are also available. Conventional jaw crusher design: Nordberg C Series jaw crusher: Nordberg C Series jaw ...

More

Jaw Crusher Components Parts - 911Metallurgist

2015年7月25日 These are bolts that have a known shear strength. If something that the crusher cannot crush accidentally gets into the crushing chamber these bolts will shear off when the Jaw hits the unbreakable object. This will prevent damage to the rest of the crusher. Unlike the gyratory crusher the main lubrication used on Jaw crushers is grease instead ...

More

The Importance of Jaw Crusher Design Features in

2023年2月28日 Jaw crushers are one of the most commonly used crushing machines in the mining and quarrying industry.They are typically used as primary crushers to reduce large rocks, ores, and minerals into smaller, more

More

The method to choose the right jaw crusher

2024年2月19日 Determine Your Requirements:Before delving into the technical details of jaw crushers, clearly define your operational needs. Consider factors such as the type and size of material to be processed, desired production

More

Gyratory VS Jaw Crushers: Advantages Disadvantages

2016年2月28日 No discussion of primary crusher selection would be complete without a comparison of the two leading types: the standard gyratory crusher and the Blake jaw crusher.Although their fields of application overlap to a considerable degree (at least in the realm of primary crushing) there is no real conflict between these two machines; one supplements

More

PEW European Jaw Crusher Primary Jaw Crusher

PEW Jaw Crusher adopts V-typed crushing chamber and tooth plate, ... Technical Consultation . Advantages. Cases. Material. Stable Structure Reliable Function. ... Details > Myanmar 500TPH Limestone Crushing Plant Details > Material Processing More. Pebble. Limestone.

More

Lokotrack® LT120E™ mobile jaw crusher - Metso

Lokotrack® LT120E™ is mobile, electric driven primary jaw crusher for aggregates production. ... The technical details provided are based on the basic configuration and should not be used for obtaining transport permits. The first models of the new Lokotrack® EC range are out now!

More

Primary Jaw Crusher Crush Power SPARES and SERVICES

Primary Jaw Crusher "CRUSHPOWER" Primary single toggle jaw crushers are suitable in quarry production lines, ... Technical Details. Modal Feed Opening (mm) Max. Feeding (mm) Discharge OPening (mm) Capacity (T/H) REV (R/Min) Power (kw) 12 x 24: 300 x 600: 250: 40 - 60: 25 - 35: 220: 37.5: 15 x 24:

More

Below the surface: Setting up an underground primary jaw crusher

2014年4月1日 Preventing objects or people from falling through the crusher, especially in a jaw crusher, where wear parts are changed quite often, is also crucial. {{image6-A:R-w:220}} Surprisingly, medium-sized objects are the most dangerous ones to lift.

More

Types of Crushers: What You Need to Know - HUATAO GROUP

2023年8月2日 Jaw crushers are large-scale, heavy-duty machinery typically constructed with cast iron and/or steel. Often considered a basic machine, jaw crushers have their place in the industry. They are often used to reduce rock into non-uniformed gravel. To find out more about primary jaw crusher check out our blog. Cross section of a Kleeman primary jaw ...

More

Jaw Crushers – MEKA

Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement ... Jaw crushers are used as the primary crushers in the first stage of a crushing process for the breaking of large-sized ... JAW CRUSHER / TECHNICAL SPECIFICATIONS. metric; imperial; MJ 60: MJ 65: MJ 90: MJ 110: MJ 130: MJ ...

More

Modeling and Improving the Efficiency of Crushing Equipment

2023年6月30日 The dependences of the current and power of the crusher electric drive on the feeder capacity are determined; the graphs have a symmetrical position relative to the approximating curve (R2 ≈ 0.9 ...

More