Used Ball Sag Mills for Sale Mining Surplus Record

Grinding mills are industrial machines used to crush and grind materials into smaller particles, typically used in mining to process ores and minerals. They operate by rotating a cylinder filled with grinding media (such as steel balls or pebbles) and the material being processed,

More

Used Grinding-equipment For Sale

Explore our extensive selection of both un-used and used grinding equipment, including ball mills, SAG mills, rod mills, and vertical mills. Regardless of the material you are mining or

More

Used Ball-mills For Sale - A.M. King

Buy used Ball-mills from A.M. King Industries. We can help guide you to the best solution for your equipment needs. Used Mining Processing Equipment - Grinding Mills, Crushers Process

More

Mineral Processing Equipment for Mining Industry

2024年8月7日 Key types include Jaw Crushers, which handle large rocks and ores through compressive force; Cone Crushers, which provide finer output for hard materials; and Impact

More

Used mineral grinding and processing machinery

Search for used mineral grinding and processing machinery. Find Raymond, Ascend, and Vostosun for sale on Machinio.

More

Minerals processing equipment - Metso Corporation - PDF

Comminution equipment Metso design and manufacture a comprehensive line of grinding mills and entire grinding systems for mining, industrial minerals industry, coal and cement,

More

Comminution Processing Equipment for Mining - Weir Group

Screening Equipment. Offering outstanding performance, using the latest in materials technology - Enduron® screens provide long service life, within even the most d High Pressure Grinding

More

Our Dynamic HPGR Technology for Mineral Grinding Weir

With low energy consumption, low maintenance requirements, excellent throughput capacity and high availability, Enduron® high pressure grinding rolls (HPGR) are a proven way to improve

More

8 Pieces of Gold Mining Equipment to Get Gold Concentrates

2023年5月27日 Grinding liberates more gold from gold ore in quartz, gold ore in granite, gold stones, gold hard rocks, tailings and black sand. Insufficient grinding causes a loss in gold

More

how a mineral grinding unit is managed - Grinding Mill China

used complete grinding unit for grinding minerals. grinding carbon black or minerals used in the filler industry, super-heated steam is usually used as the grinding Cement Grinding

More

Grinding Methods for Four Kinds of Phosphate Ores - Xinhai

2023年10月19日 During the grinding and flotation processes, over-crushing should be avoided, which is of great significance to reducing grinding costs, improving mineral processing indicators and processing of concentrate products. The coarse-grained phosphate rock can complete the basic dissociation of phosphorus-containing minerals after a period of grinding.

More

Potentials of grinding process simulations for the

Various cutting materials and bond types can be used for grinding tools, ... Potentials of grinding process simulations for the analysis of individual grain engagement and complete grinding processes. Front. Manuf. Technol.

More

(PDF) Effects of Grinding Aids Used in Grinding

2021年12月31日 Most of these minerals are deposited in nature from rocks but also from waters, countless plants and animals [6,7]. This substance, generally used in building since the time of ancient Egypt, is ...

More

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年11月14日 Grinding media play an important role in the comminution of mineral ores in these mills. This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as influenced by three basic wear mechanisms: impact, abrasion, and corrosion.

More

(PDF) Energy-Model and Life Cycle-Model for Grinding Processes

2022年5月22日 Normalized and weighted values in the wet grinding process in nanograms. (Functional unit: 1 kg of limestone product. Impact assessment method: CML 2001/Aug. 2016.

More

Mineralogical Specimen Preparation A Complete Range of

Table unit With compartment for recirculating cooling unit. 05116916 Diamond Cup Wheel M0P15 Metal bonded, for grinding of hard, brittle materials on Discoplan-TS. 40800013 Diamond Cup Wheel B0P15 Resin bonded, for grinding of hard, ductile materials on Discoplan-TS. 40800014 Diamond Cut-off Wheel M4D20 For cutting of minerals and ceramics (HV ...

More

Mineral Processing Equipment for Mining Industry

2024年8月7日 Key Considerations for Choosing Mineral Processing Equipment. Selecting the right equipment involves evaluating several factors: Mineral Type and Characteristics: The type and properties of the mineral affect equipment selection. Choose equipment that can efficiently handle the mineral’s hardness, abrasiveness, and chemical properties.

More

used complete grinding unit for grinding of minerals

Crsine HTML Template For Car Services. Call Agent. 0086-21-58386256. Call Agent [email protected] ... used complete grinding unit for grinding minerals - Used Cement Grinding Unit - crusher machine for sale- used complete grinding unit for grinding minerals,Cement grinding unit is an ideal large grinding equipment, widely used in cement, ...

More

Comminution a Heart of Mineral Processing - ResearchGate

2021年7月6日 Grinding in mineral processing is achieved using rod mills, ball. mills, SAG mills, etc. ... [Show full abstract] unit or the dry ball mill at essentially the same grinding degrees.

More

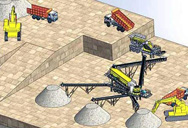

MINERAL PROCESSING - MILLING - United Diversity

In this brief we will concentrate on mineral grinding, rather than the grinding of grain and other dykrt6rdeyk 1 Figure 1: Swing hammer mill being used for lime milling in ... The milling circuit is the complete mill system from beginning to end, including feed mechanism, mill, classifier, separator, product collector, etc.

More

Energy Use of Fine Grinding in Mineral Processing

2013年4月25日 as polishing the mineral surface, which can enhance recovery. DOI: 10.1007/s40553-013-0001-6 The Minerals, Metals Materials Society and ASM International 2013 I. INTRODUCTION FINE grinding is becoming an increasingly common unit operation in mineral processing. While fine grinding can liberate ores that would otherwise be considered

More

Minerals Grinding - Pulveriser Machine Manufacturer

Used in industries like powder-making production line like of silicate, refractory material, cement, fertilizer, ferrous metal and others; Works flawlessly; Offers combination of materials, ranging from 5-30 mm onwards product sizes; Used

More

11 types of grinding equipment commonly used in the non

2024年1月17日 For non-metallic mineral grinding, the choice of processing equipment is very important. Different types of grinding equipment are suitable for minerals of different attributes, and have specific correspondences to hardness, raw material size, humidity, output, etc., and understanding the working principle, performance characteristics and scope of application of

More

Cryogenic Grinding - NETZSCH Grinding Dispersing

2017年5月11日 NETZSCH offers this innovative technology as a complete system, tailor-made to suit each customer´s requirements, in general with a complete grinding plant, a Condux ® Impact Mill and a compatible screening machine. A packing unit, which is

More

Increased grinding capacity with technology from Metso Outotec

Grinding is an essential part of the slag concentration process. The order has been booked in Metso Minerals’ Q2 2020 orders received. Based on tests ... Metso Outotec is launching yet another powerful product in its range of concentrator plant units the complete Stirred Mill Plant Units for efficient fine grinding. The units integrate ...

More

Grinding Mills in the Mineral Processing Industry - MechProTech

2024年7月19日 Applications of Grinding Mills in Mineral Processing. These mills are widely used in grinding various ores and minerals, including gold, copper, iron, and zinc. As previously mentioned, grinding mills are integral to the comminution process, which crushes ores to separate the valuable minerals from the gangue.

More

11.24 Metallic Minerals Processing - US EPA

dry grinding processes are used, PM emissions can be considerable. After final size reduction, the beneficiation of the ore increases the concentration of valuable minerals by separating them from the matrix rock. A variety of physical and chemical processes is used to

More

Fine Grinding and Dispersing - Mineral Processing

Grinding and dispersing with stirred media mills (Fig.) represent important process steps in many branches of industry. The course gives an overview about the physical phenomena of grinding and dispersing in stirred media mills, and shows how this knowledge can be used for the design and optimization of grinding and dispersing processes.

More

Grinding and Finishing - IIT Bombay

Grinding – Ex. 1-1 • You are grinding a steel, which has a specific grinding energy (u) of 35 W-s/mm3. • The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2. The motor has a power of 2 kW. • The work piece moves (v) at 1.5 m/min. The chip thickness ratio (r) is 10.

More